A great deal of caution must be applied when choosing suitable metals for the manufacture of surgical instruments. Due to the sensitivity of the medical field, there are specific criteria that the materials used in the production of these instruments must meet. This is because a wrong material choice could cause severe effects.

Typically, metals are the common material for making medical equipment because medical equipment requires high strength and durability. Though metals are the ideal choice material for surgical instruments, not all metals meet the required standards. This article will discuss the metal requirements for surgical instruments used by medical device manufacture or prototype companies and the metals that fit those criteria.

Metal Requirements in Surgical Instruments

Every metal has its specific properties, and it is vital to select the ones whose properties suit the criteria of each type of surgical instrument. The following are the requirements metals used in surgical instruments must meet:

● High Degree of Protection Against Corrosion

Surgical instruments are constantly exposed to bodily fluids, water, and cleansers, containing chemicals that can cause corrosion. For example, chloride ions which may cause corrosion are present in bodily fluids like blood and pus. Also, the tap water used to wash these instruments may have minerals like chlorine, magnesium, and sodium in large quantities. These can cause severe corrosion on the tools.

In addition, cleansers used to sterilize the instruments are either alkaline or acidic, with different pH levels. These solutions may also make these surgical instruments susceptible to corrosion over time. Thus, it is vital for prototype companies making medical equipment to use metals that are corrosion resistant to eliminate this problem.

● Biocompatible Materials

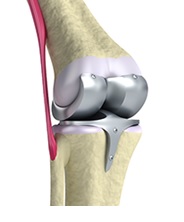

Biocompatibility describes a material’s property of being compatible with living tissue. Some of this equipment is inserted directly into the body, for example, replacement joints. Therefore, they must be made from materials that are non-toxic or produce any immunological response in the presence of the body or bodily fluids. Some elements like Nickel, Chromium, and Cobalt are associated with tissue hypersensitivity problems and allergic reactions.

● Non-Magnetic Materials

Sometimes, surgical instruments are exposed to a magnetic field that is generated in the operating room. For example, MRI produces a magnetic field of approximately 1.5 Tesla. This can affect the instruments in many ways.

The magnetic field interactions could create unwanted movement; tools could also become heated due to radio frequency power disposition. So, non-magnetic materials such as titanium, steel, and alloys are highly recommended in the production of surgical instruments.

● Good Ductility

These metals used should possess good ductility, as many of the surgical instruments are thin and long and ductility.

Surgical instruments should be made from metals that can easily be made into different shapes without breaking.

5 Common Metals Used for Surgical Instruments

Here are the most commonly used metals for surgical instruments. These metals are ideal as they possess the necessary requirements listed above. Consequently, they are the go to materials for prototype companies that deals with surgical instruments manufacturing.

● Stainless Steel

Stainless less is commonly used for material for different medical appliances. It is widely used in tools like tweezers and forceps and orthopedics for replacement hip joints or screws to stabilize bones.

This metal is non-toxic, corrosion and rust-resistant, and highly durable. It also non-magnetic and easy to clean because it is polished to a very fine finish.

Stainless steel can withstand high temperatures. Therefore, it can be sterilized in an autoclave at 180oC. Its outstanding strength to weight ratio makes it a metal fit for use in surgeries. Flexibility, hardness, tensile strength, and malleability are considered when choosing steel. These are based on the instrument’s intended use. The stainless quality comes from its chromium content which forms a thin layer on the surface for protection against corrosion. Also, depending on the carbon content of the steel, some can be hardened while others cannot.

Due to their corrosion-resistant property, 316 and 316L stainless steels are commonly used in medicinal implants and piercings.

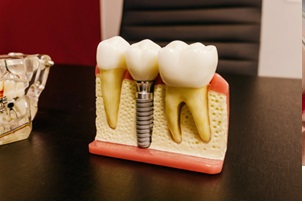

● Titanium

Titanium is an excellent substitute for stainless steel and is becoming widely popular in the production of implantation devices. It is equally as durable and strong as stainless but lighter and more flexible. Titanium is corrosion-resistant, fuses well with bones, and its high biocompatibility makes it a perfect fit for orthopedic rods, plates, and dental implants.

This metal is more heat resistant than stainless steel and can withstand high temperatures. It is a tough, durable, and versatile metal that is suitable for different medical purposes. Its lightweight property makes it beneficial for the production of microsurgical instruments, as it prevents surgeon fatigue.

● Tantalum

Tantalum is a refractory metal with a high melting point. It is strong, ductile and its high biocompatibility makes it attractive in the medical industry. This metal is resistant to bodily fluids and resistant to corrosion to be utilized for surgical instruments without detrimental effects. It is also an excellent choice for implants and bone replacement and can easily be formed into thin wire due to its ductility. Its malleability allows it to be developed into different shapes.

● Platinum

Platinum is a precious metal with properties that make it fit for medicinal purposes. It possesses excellent malleability and ductility, making it easy to form various shapes like sheets, tubes, wires, rolls, etc. The metal is corrosion-resistant, strong and durable, and inert. Thus it won’t cause damage when in contact with internal organs.

It has popularly been used in producing the ultra-thin wires that surgeons use for positioning implants in recent times. Platinum has good electrical conductivity and high biocompatibility, making it an ideal material for medical devices like cardiac pacemakers, defibrillators, and catheters.

Palladium

Palladium is also an expensive metal that has similarities with Palladium both in properties and functionality. The differences between Palladium and Platinum are in density, mass, melting point, and price, with Palladium being cheaper. It is durable, malleable, ductile, and highly resistant to corrosion.

This metal is useful in making intricate parts that are suitable for precision surgical instruments. Palladium is widely used in dental materials, it is inert and has no severe effect on the body or internal organs. It is also highly visible in X-rays and ideal for use as markers on implants.

Conclusion

Metals used in the production of surgical instruments must meet a high standard as it is essential to protecting health and life. However, not all metals meet these requirements. Some common criteria for choosing these metals are durability, resistance to heat and corrosion, ductility, and biocompatibility. This article provided information about common metals utilized by different prototype companies in making different surgical instruments and their properties.