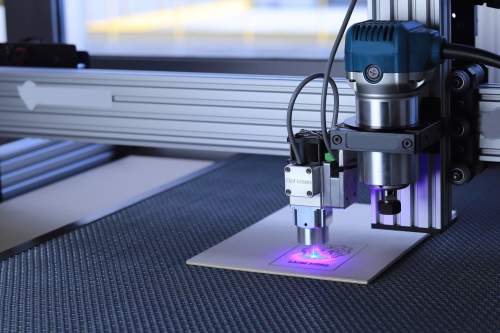

Laser marking is a unique process that processes materials with a laser beam and is divided into different procedures: engraving, discoloration, removal, etc.

In recent years, laser marking system has become very popular due to the numerous advantages it offers and, above all, for the results. it guarantees impeccable processing that hardly requires additional corrections without forgetting that the marking dramatically reduces the production times and can be used on many materials: wood, jeans, paper, ceramic and many others.

Impeccable and lasting results

This technology guarantees extraordinary decorative results, achievable without difficulty and very long-lasting. The material structure on which it is applied is modified; therefore, the decorative effect will remain indelible forever. In the case of complex, articulated geometric shapes. The final impact will always be perfect and uniform.

There is not direct contact between the laser system and the material to be treated with laser marking, so the risk of damage is considerably reduced. This aspect is to be considered, especially in the case of delicate surfaces such as ceramic and glass that require attention.

Laser marking is environmentally friendly.

In an era where respect for the environment becomes a priority, laser marking is presented as an environmentally sustainable process, and the creation of ecologically sustainable products, such as packaging, is also preferred.

High marking speed and flexibility

Laser marking system is one of the fastest machining processes in existence, and this allows a significant increase in productivity and economic savings. Laser systems also have broad flexibility of use. With the usual approach and without modifications, this technology enables marking, engraving, and cutting by changing only the power and speed.

Perhaps you would first have to list the materials that cannot be treated with the laser!

Laser marking is, in fact, suitable for carrying out any decoration and personalization on objects of different materials and even of various sizes, from the smallest to those with larger surfaces.

Laser marking of the skin

One of the most successful processes! The marking laser is used in the clothing and leather goods sector to create refined decorations and floral or geometric motifs that make each garment special.

For perforating, cutting, and decorating leather, the laser is the right choice also because there is no contact between the material and the system, so the risk of errors and damage is practically zero.

Laser marking of the fabric

There has never been a more successful combination than that between laser and fabric! In the furniture, fashion, or automotive sector, where the aesthetic component has a significant weight, decorating the material with care determines the success of a product. Embossed designs on thick fabrics or microfibers or the vintage effect on jeans are just two examples of the results achieved thanks to laser marking.

Laser marking of the jeans

We know well how many procedures harmful to the environment require the processing of jeans, especially the one necessary to replicate the much loved vintage effect. The laser eliminates this problem and has revolutionized the fashion industry, replacing the more traditional methods. From cutting to finishing, the laser becomes an absolute protagonist that removes chemicals and guarantees impeccable finishes, indispensable in a sector such as fashion.

Laser marking of the glass

Glass is also very suitable for laser processing; in the furniture and design sector, in general, and specialized objects, such as that dedicated to the wine world.

Laser marking of wood

The finest woods and the most common ones are easily marked with the laser, recreating any graphic sign, design, text, logo, etc. In a short time, representations and engravings are reproduced serially and automatically. Laser marking on wood resists over time, has a visual impact in line with craftsmanship and tradition, and does not require subsequent processing.

Laser marking of ceramics, marble, stones

Despite being fragile and delicate materials, even ceramics, marble, and stones lend themselves optimally to laser marking, with which sharp and defined engravings are obtained. The absence of contact between the laser system and the material prevents any breakage or surface stress.

Laser marking of the card

Business cards, invitations, greeting cards, brochures, invitations, packaging… how many paper objects we handle daily and how many of these are made with a laser decoration. Each piece of paper becomes a small personalized work of art with drawings, writings, and logos.

Please check our this website moving companies san diego